脱硫脱硝

在环保要求日趋严格,企业的社会责任也日益被关注的当下,我院作为国内建材行业最早的设计研究院之一,积极主动的投身于建材行业烟气综合治理与利用中。我院在多年的探索、总结与创新后,主要形成了以下五类烟气治理技术:

1、石灰石-石膏湿法烟气脱硫技术;

2、CFB循环流化床半干法脱硫技术;

3、SCR脱硝技术;

4、SNCR烟气脱硝技术;

5、氧化吸收法脱硫脱硝技术。

我院先后承接了众多玻璃窑炉、水泥窑的烟气治理工程的咨询、设计、技术服务、设备成套和总承包工作。在治理烟气的同时,我院还结合自身的余热利用技术成熟的特点,为业主量身定制最优方案降本增效。

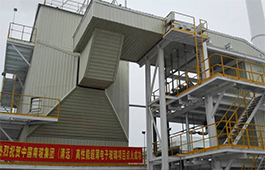

由我院总承包的吴江南玻玻璃有限公司烟气综合治理及利用项目,针对南玻现有一条600t/d和900t/d的生产线进行余热利用和废气治理技改。该项目为国内第一条玻璃生产线配套SCR脱硝系统。

由我院总承包的青岛圣戈班玻璃有限公司620t/d玻璃窑烟气脱硫脱硝除尘项目,是采用半干法脱硫+静电除尘+SCR脱硝组合工艺,实现了废气先脱硫除尘,再脱硝,脱硝后烟气余热综合利用的模式,打破国内传统的先脱硝再脱硫除尘的模式。

由我院总承包的株洲旗滨集团450t/d和550t/d玻璃窑脱硫除尘项目,采用“石灰--石膏法脱硫+文丘里除尘”组合工艺对其进行脱硫除尘烟气治理,该项目作为国内首批玻璃行业配套的脱硫除尘系统,荣获中国建材集团小型窑炉脱硫除尘技术科技进步奖三等奖。